Food

Quality, efficiency, success – precision measurements for food manufacturers

Harrer & Kassen’s sophisticated measuring systems are designed to meet the challenges of the food industry. Specially developed for the accurate measurement of water content, dry matter and other essential parameters, our systems enable precise analysis of various products. By precisely determining relevant measured values, we set standards in quality and support users in meeting strict quality requirements and optimizing production processes. The result: consistent quality, minimized waste and considerable cost savings for our customers.

Our measuring devices are used in the following areas of the food industry

Why process measurement technology is crucial in the food industry:

Quality control

Precise measurements ensure the consistent quality of food products by monitoring various parameters during production. This enables the creation of control loops to maintain consistent product quality.

Increase in efficiency

Precise measurements optimize processes, use resources more efficiently and thus enable cost savings and waste minimization.

Reproducibility

Accurate measurement and control of process parameters enable high reproducibility to ensure that food products are consistent and of high quality.

Legal requirements

Process measurement technology helps to maintain quality standards, facilitates the documentation of production processes and contributes to the fulfillment of legal requirements.

Real-time monitoring

Advanced measurement technology enables real-time monitoring of processes in order to react quickly to deviations and minimize the risk of production errors.

Traceability

Process measurement technology supports traceability in the food industry by collecting relevant data on the entire production process and identifying the origin and route of the raw materials.

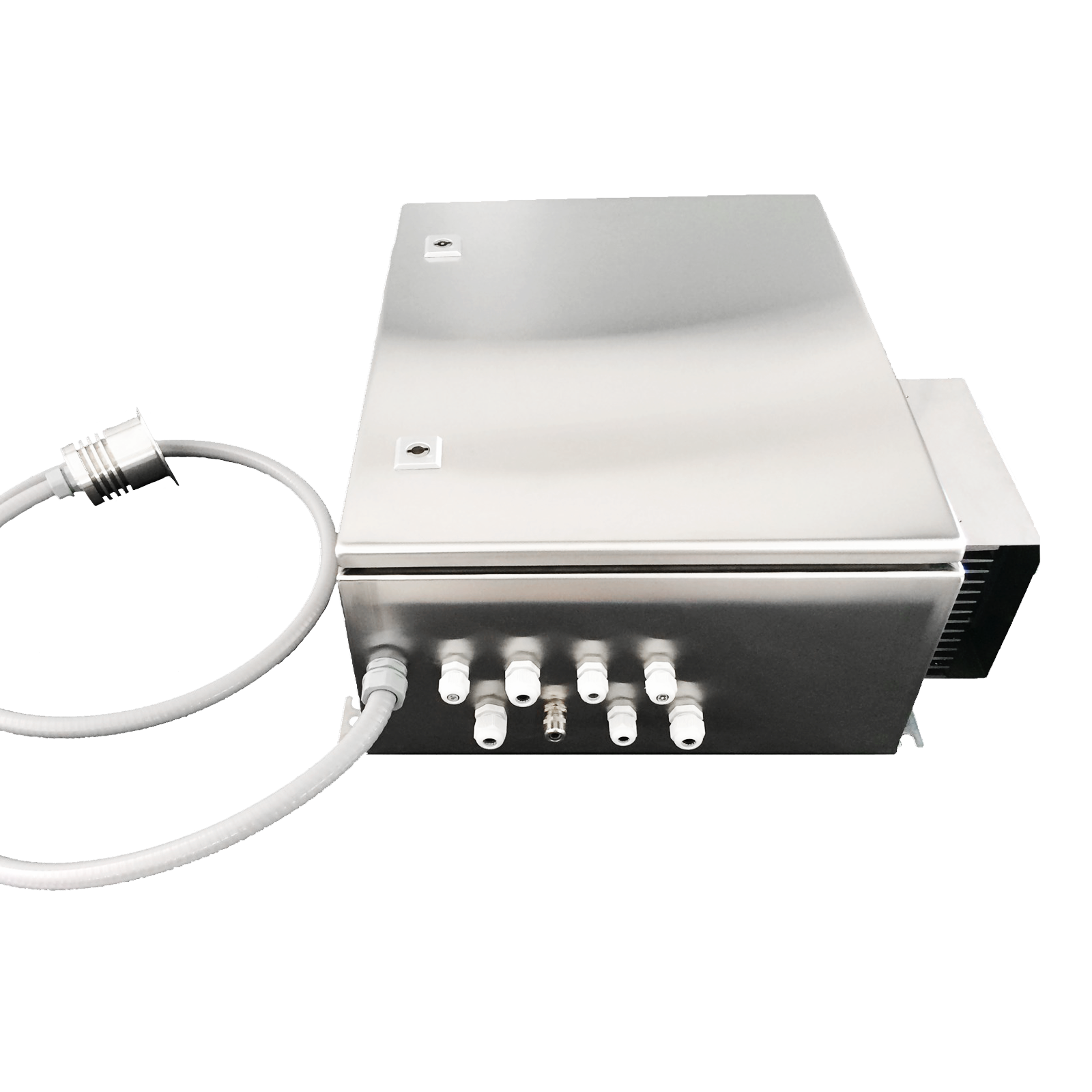

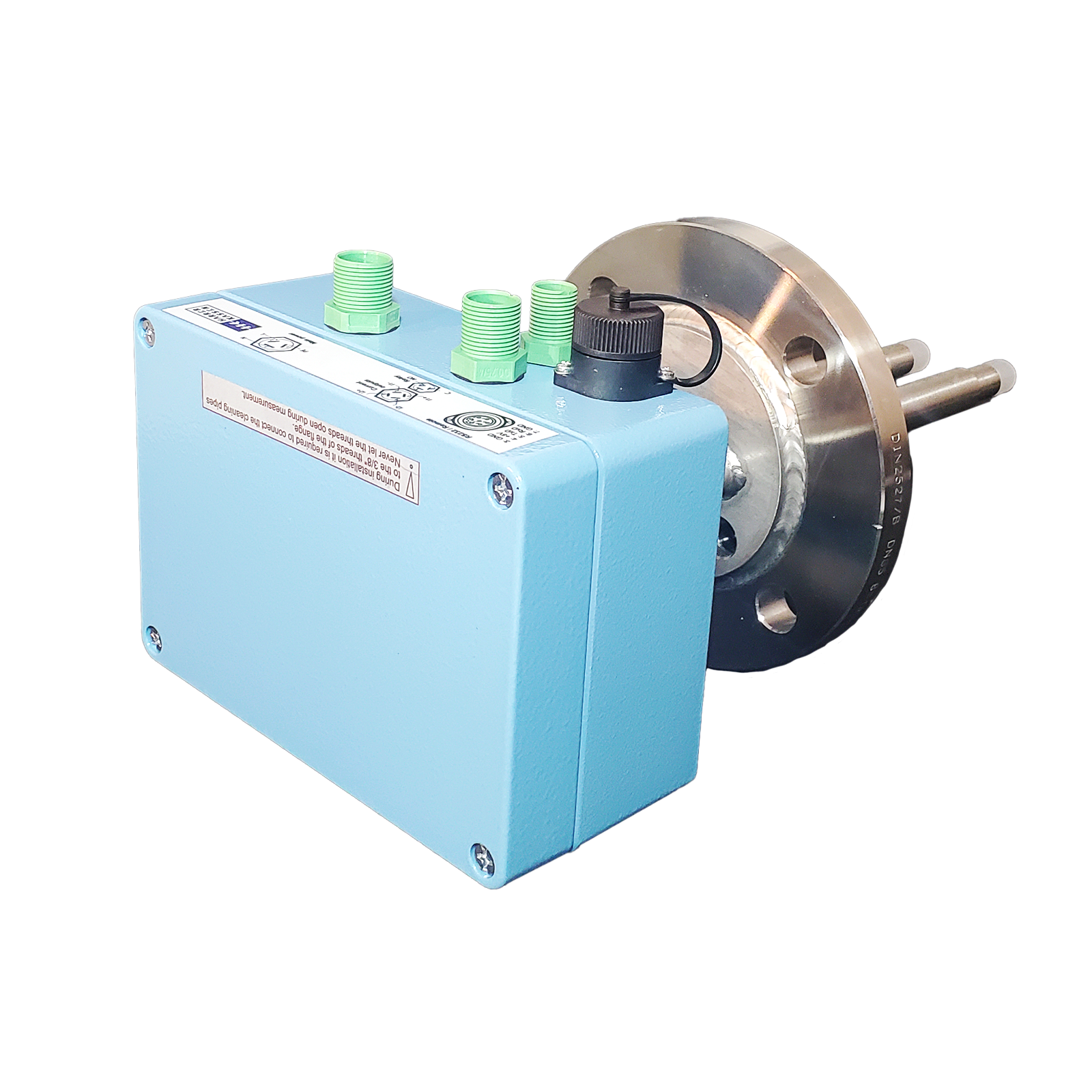

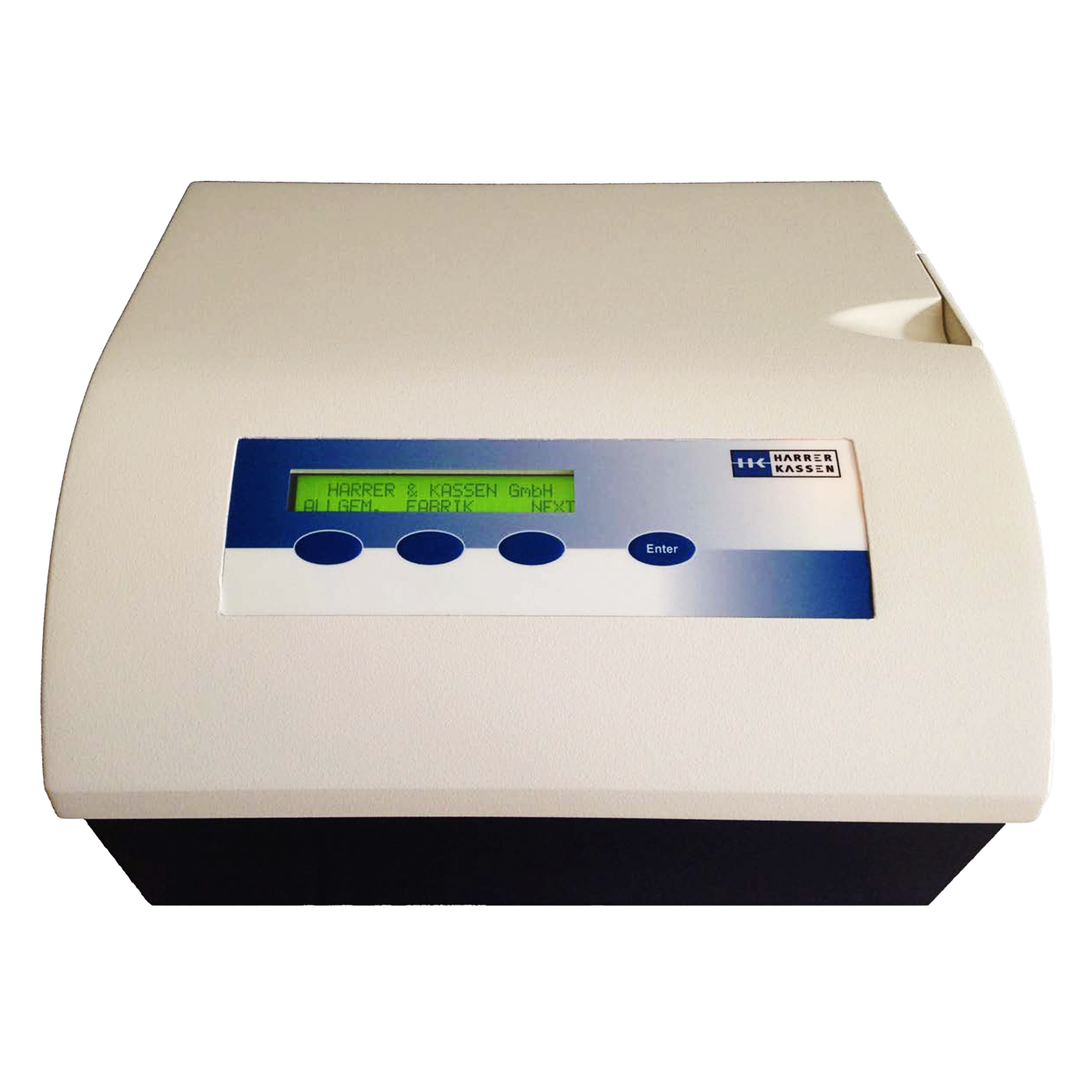

Our products for the food industry

Industries: Waste water, chemical industry, dairy, starch, tobacco (tobacco cuttings), animal feed

Industries: Waste water, chemical industry, dairy, starch, tobacco (tobacco cuttings), animal feed

Industries: Gypsum, chemical industry, meat, dairy, mill products, cheese dairy, animal feed, other (blood)

Industries: Waste water, gypsum, floor coverings, sand, wood, clay, fiberboard, chemical industry, dairy, starch, sugar, paper, tobacco (tobacco cuttings), animal feed

Industries: Waste water, gypsum, floor coverings, sand, wood, clay, fiberboard, chemical industry, dairy, starch, sugar, paper, tobacco (tobacco cuttings), animal feed

Industries: Chemical industry, meat, dairy, cheese dairy, starch, mill products, animal feed