HK5

The HK5 is a powerful spectrophotometer for continuous in-line measurement of color and organic components – non-destructive and highly precise. The system is ideal for use in pipelines, tanks, containers or above conveyor belts – for example in the food, textile, plastics or metal industries.

Thanks to its modular design, the sensor can also be installed in places that are difficult to access, while operation is convenient via the evaluation unit. The integrated calibration function and the open calibration software allow maximum flexibility when adapting to individual processes.

Features at a glance

Product description

The HK5 works on the basis of spectrophotometry and uses continuous LED illumination to measure the color and organic components of a product in real time. The system is specially developed for the CIELAB color space, which is used to objectively determine color differences and reflects human perception as accurately as possible.

The measurement is carried out by directing the light through the sensor onto the product to be measured. The reflected light is then recorded and analyzed by a detector. The sensor measures the intensity and spectral composition of the reflected light in the visible range and in the near-infrared range (NIR). This measurement enables the precise determination of color (CIELAB values) and organic components (e.g. moisture or sugar content) in the product.

The modularity of the system makes it possible to install the sensor in places that are difficult to access, such as in narrow pipelines or above conveyor belts, while the evaluation unit can be conveniently placed in another, easily accessible location. The spectra of the product are recorded directly on the sensor using a calibration probe and stored in the device’s internal memory. These spectra can later be read out with the calibration software and used to validate and further adjust the measurements.

Thanks to the open calibration, existing calibrations can be extended or new ones created at any time. This flexibility is particularly advantageous in dynamic production environments where the properties of the product can change over time.

Thanks to the continuous measurement and real-time monitoring of the product, faulty production can be detected at an early stage so that immediate adjustments can be made to the production process in order to maintain consistent product quality.

Applications:

LAB color wheel: Visualization of the color dimensions a* and b*

In this interactive visualization of the CIELAB colour space, you can see how colors behave along the a*-b* axes. The slider can be used to change the L* value (brightness), which adjusts the entire color wheel accordingly. This makes it clear how light and color interact in the LAB model.

The RGB color space cannot display all colors of the LAB model exactly, as it is more limited in its color spectrum.

What sets the HK5 apart

Modular design & flexibility

The sensor and the evaluation unit are separate, which enables flexible installation in hard-to-reach places. Operation is convenient via the evaluation unit, even if the sensor is mounted far away.

Continuous LED lighting

In contrast to xenon flash lights, the HK5 uses long-life LED lighting (at least 10 years), which ensures stable and reliable measurement.

Real-time measurement & open calibration system

The HK5 enables continuous measurements in real time and offers an open calibration system that allows extended or new calibrations directly by the user.

Non-destructive measurement & ease of maintenance

The non-invasive measurement keeps the product intact, while the optical components with no moving parts ensure low maintenance and a long service life.

Technical data

Measuring method

Spectrophotometry with CIELAB and NIR measurement

Assembly technology

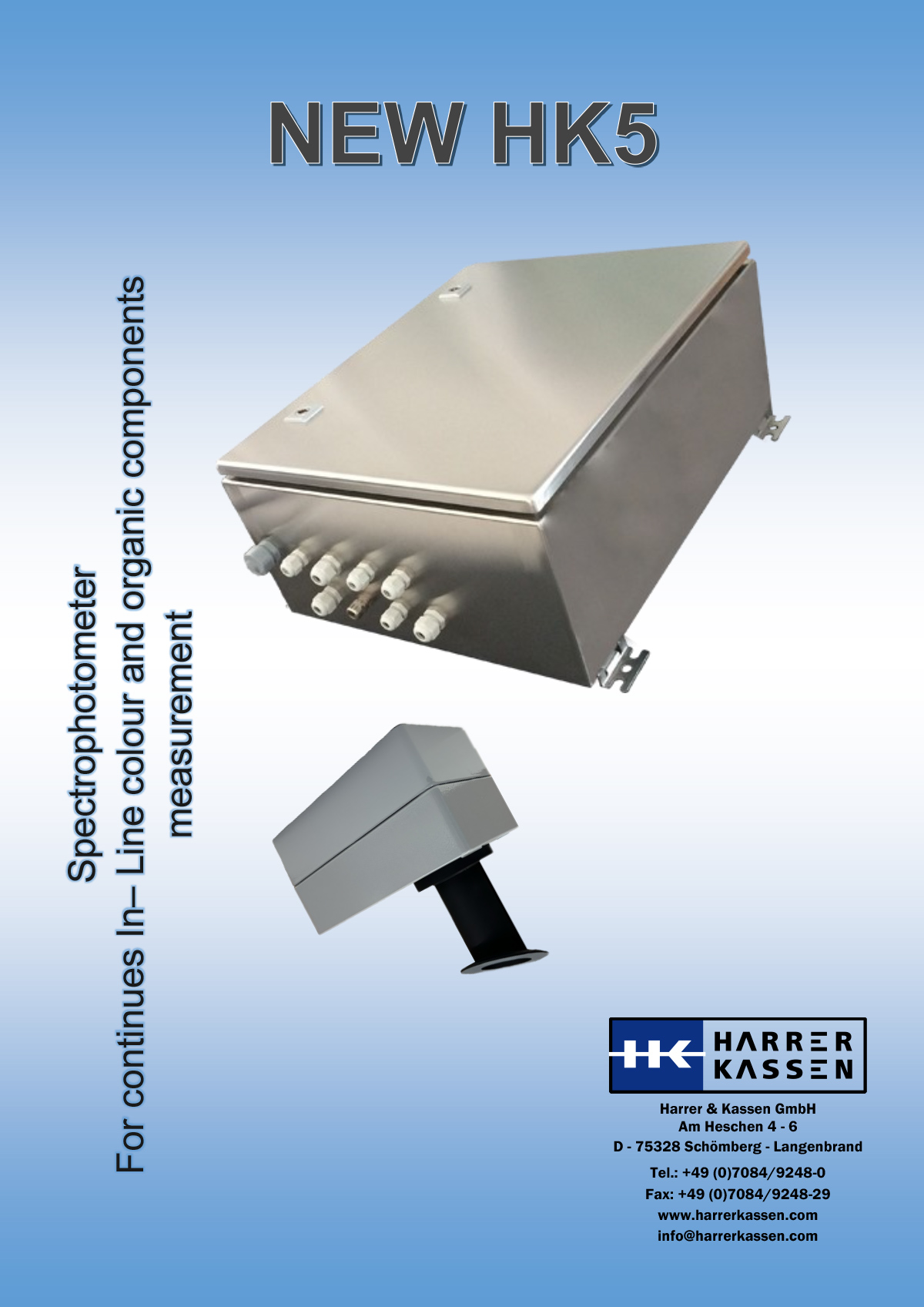

Stainless steel housing (evaluation unit):

400 x 499 x 212 mm

Die-cast aluminum housing (sensor):

120 x 220 x 90 mm

280 x 230 x 110 mm

Weight (evaluation unit):

approx. 20 kg

Weight (sensor):

approx. 4 kg

IP66 / NEMA 4

Connections

Power supply:

85 – 265 V AC, optionally 24 V DC

Analog outputs:

2x 4 – 20 mA, isolated 1,500 V

PC interfaces:

RS 232 or RS 485

Digital inputs:

Ext. start/stop

PROFI-BUS-DP:

User interface

Operation:

6 softkeys integrated in the membrane keypad

Display:

2x 24 character LCD, LED illumination

Temperature ranges

Ambient temperature:

-20 °C to +40 °C

Product temperature:

–

Seniors

Design:

Spectrophotometer sensors

PC requirements

Processor:

min. 300 MHz clock frequency, recommended Pentium III processor (or faster)

Operating system:

Windows 7 (32 and 64 bit) or higher

Working memory:

512 MB RAM (or higher)

Connection:

USB interface