Mill products

Customized measurement technology for the milling industry

The production of flour, meal and other milled products requires maximum precision and control to ensure consistent quality and efficiency. The innovative measuring solutions from Harrer & Kassen provide milling companies with precise technologies for monitoring water content and other essential parameters.

Our measuring systems offer tailor-made solutions that optimize production processes, minimize waste and ensure the quality of the end products.

Precise monitoring for consistent quality

Our measuring devices are tailored to the requirements of the milling industry. They measure the water content and specific ingredients with maximum accuracy.

Our technologies deliver robust and reliable results, even at high throughput rates and under demanding conditions

Your advantages

Versatile application options for our measuring devices

Grain drying

Moisture measurement for optimum shelf life

Our microwave measurement technology precisely monitors the moisture content during the drying process. This is essential to ensure the shelf life of the grain and prevent mold growth.

Grinding

Dry matter control for consistent flour quality

During the grinding process, our measuring technology continuously measures the dry matter content to ensure that the desired quality standards for flour or meal are met.

End product monitoring

Quality control of flour and meal

NIR spectrometers make it possible to analyze protein and starch concentrations in the finished flour to ensure that products meet customer requirements.

What sets our solutions for mill products apart

Optimization of moisture and ingredients

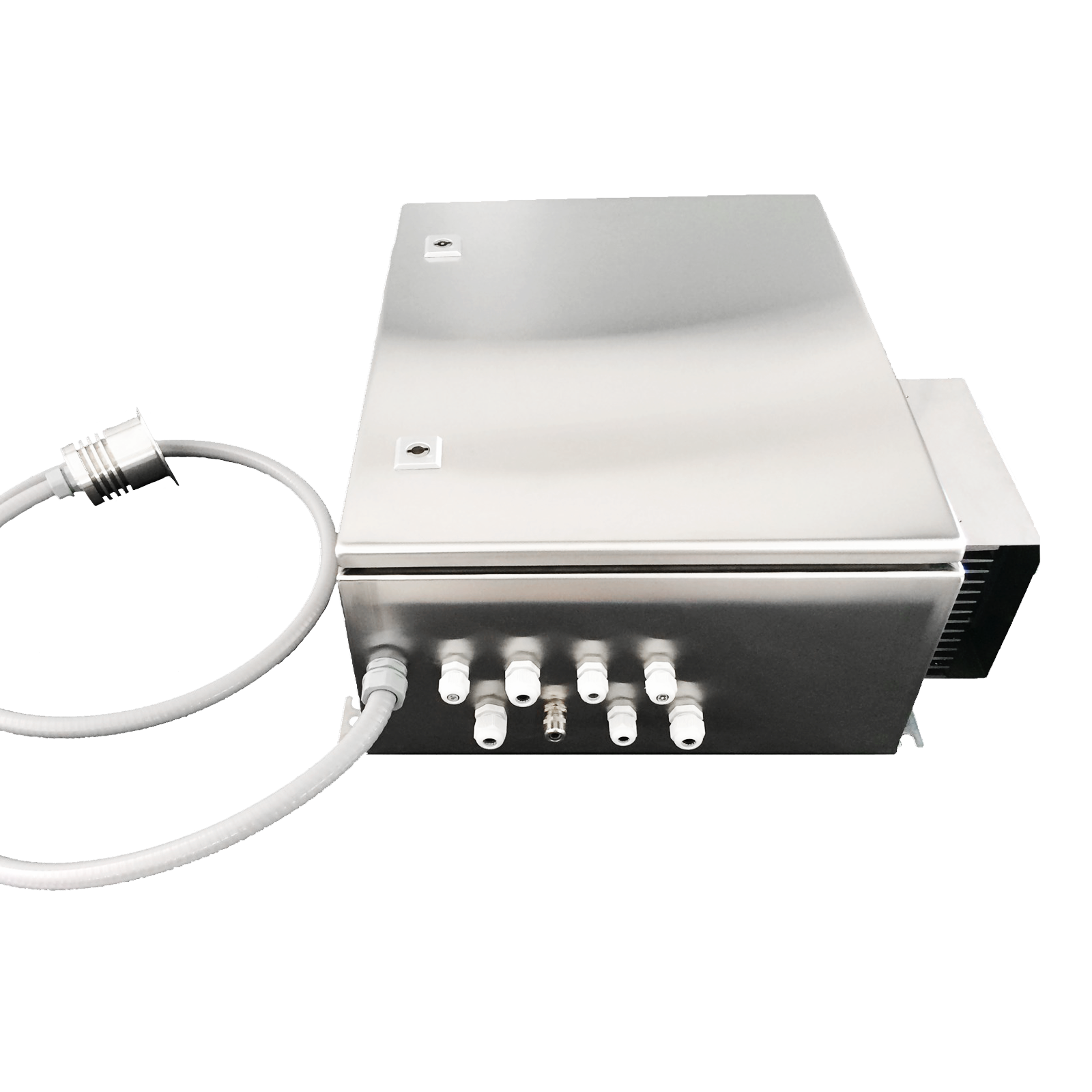

Precise monitoring and control of process parameters is essential for the production of high-quality milled products. Our microwave measuring systems and NIR spectrometers record relevant parameters such as water content or protein and starch concentration with the highest accuracy. This enables finely controlled adjustment of the production processes so that milled products can be optimally tailored to the requirements of the market and customers.

Efficient use of raw materials

Our measurement technology ensures that raw materials are used efficiently by guaranteeing precise dosing and avoiding overdosing. This is not only economical, but also conserves valuable resources.

Particularly in the milling and mixing of grain, precise control of the parameters ensures that only as much is used as is required to achieve the desired quality,

Consistent product quality

Consistent quality is a decisive competitive factor in the milling industry. Our solutions use continuous measurements and real-time monitoring to ensure that all products meet the specified quality standards.

From the raw material to the end product, every phase of the production process is optimized to minimize fluctuations and deviations.

Reduced waste

Rejects and production losses are not only a burden on the environment, but also increase costs. Thanks to the precise control and monitoring of moisture, dry matter and ingredients, our systems reduce deviations and prevent unnecessary losses. The result: less waste, greater sustainability and more efficient production.

Our measurement technology thus creates the basis for economical, sustainable and future-oriented production in the milling industry.

Our products for the milling industry

Industries: Gypsum, chemical industry, meat, dairy, mill products, cheese dairy, animal feed, other (blood)

Industries: Chemical industry, meat, dairy, cheese dairy, starch, mill products, animal feed