HK3 mini

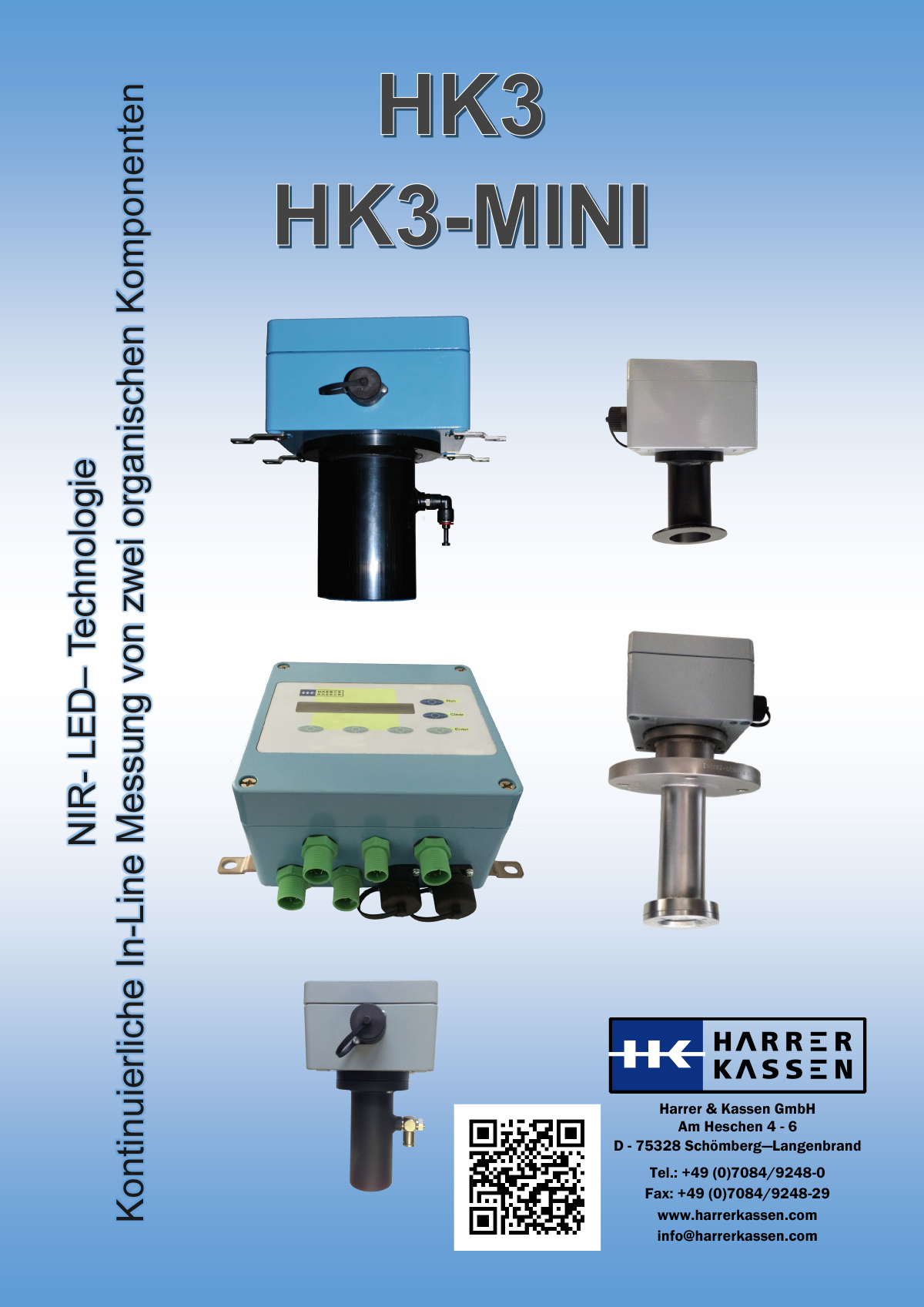

The HK3 mini is a powerful NIR analyzer for the continuous measurement of two substances – e.g. water and protein – directly in the process. Thanks to its compact design and modular structure, it is particularly suitable for confined installation situations, whether on pipelines, in containers or for non-contact measurement above conveyor belts.

The innovative LED NIR technology enables precise, stable and low-maintenance analysis of a wide range of products – without any moving parts. This makes the HK3 mini a reliable partner for real-time measurement and process optimization in the food, animal feed and chemical industries.

Features at a glance

Product description

The HK3 mini combines precise measurement technology with a space-saving design. Based on NIR reflection technology, the system continuously records two ingredients, such as the moisture and protein content of a product. This is done non-destructively and in real time – directly in the running process.

Measurement takes place either directly in the product by immersing the sensor via flange mounting or contactless through a viewing window. Applications on conveyor belts are also possible without any problems. Inspection windows made of borosilicate or sapphire glass can be used for hygiene-critical or abrasive products.

The system has a modular structure

The sensor and evaluation unit are connected via a shielded cable, which allows for flexible installation. The intuitive calibration and operating software allows the user to store up to four products, each with two calibrations, in the device and quickly switch between them.

What sets the HK3 apart

Two-component measurement in real time

In contrast to conventional NIR systems, the HK3 mini simultaneously detects two ingredients – moisture and protein, for example – without the need for multiple sensors. This saves space, time and investment costs.

Compact & flexible in use

Thanks to its compact design, the device also fits into confined plant environments. The sensor can be immersed directly in the medium or measure contactlessly through a viewing window – ideal for use on conveyor belts, in tanks or pipelines.

Modular design for easy integration

The sensor and evaluation unit are physically separated and connected to each other via a cable. This allows the sensor to be installed in hard-to-reach places while the operating unit remains easily accessible – e.g. in the control cabinet.

Reliable measurement results without maintenance

The system works with a wear-free LED light source with a service life of up to 10 years. As there are no moving parts, the HK3 mini is virtually maintenance-free and delivers stable, drift-free results even under harsh conditions.

Technical data

Measuring method

NIR reflectance measurement

Assembly technology

Die-cast aluminum housing:

120 x 120 x 90 mm or

230 x 200 x 110 mm

IP65 / NEMA 4

Connections

Power supply:

100 – 240 V AC optional 24 V DC

Analog outputs:

2x 4 – 20 mA

PC interfaces:

RS 232 or RS 485

Relay contacts:

1x max. 5 A / 250 V

Digital inputs:

Ext. selection for 16 products, start, stop

PROFI-BUS-DP:

User interface

Operation:

6 softkeys integrated in the membrane keypad

Display:

2x 24 characters with backlight, LED illumination

Temperature ranges

Ambient temperature:

-20 °C to +50 °C

Sensors

Design:

LED illumination with NIR LEDs