Product description

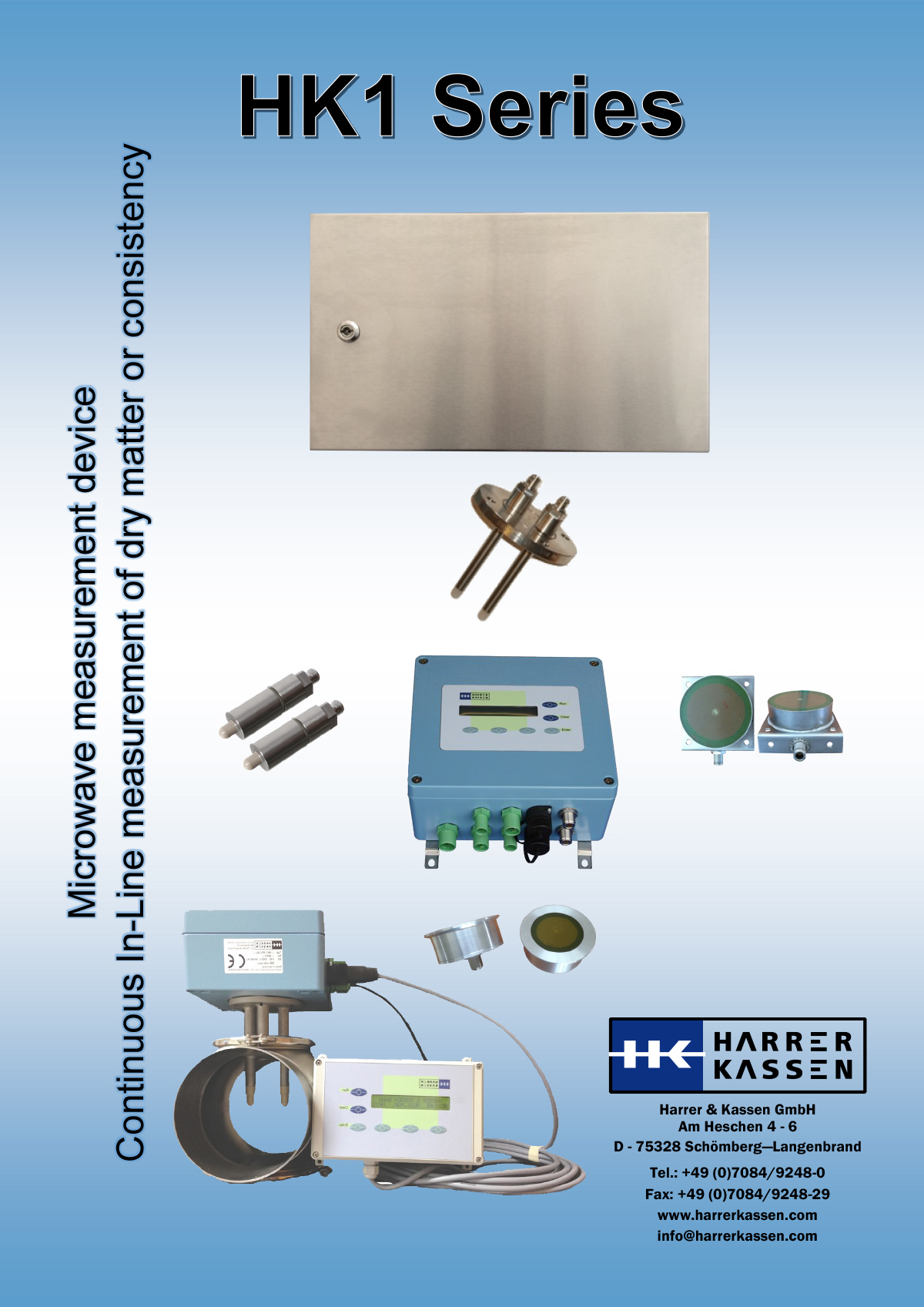

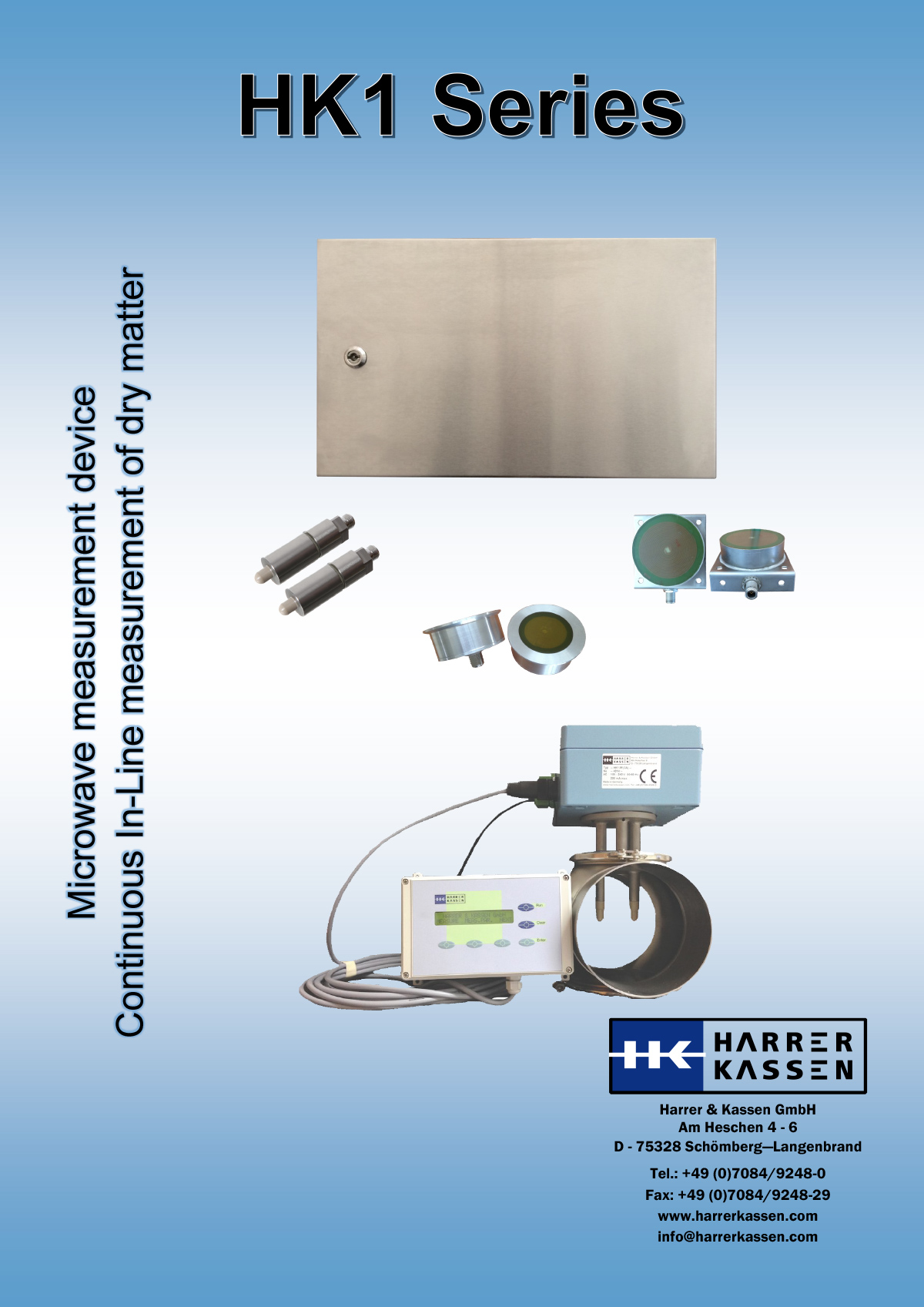

Developed for the highest demands in the cheese industry, the HK1-MC microwave measuring device presents an innovative solution for determining the dry matter or water content of cheese blanks on conveyor belts. With advanced microwave technology in the ISM band, this device sets new standards in precision and efficiency.

The mode of operation is based on the generation of low-power electromagnetic waves that penetrate the cheese product. The propagation of these waves depends on the dielectric properties of the cheese. A second antenna receives this wave (transmission) and the power and phase position serve as decisive units of measurement for the water content or dry matter.

The HK1-MC is the world’s only on-line measuring device for measuring the water content or dry matter of individual cheese blanks on conveyor belts. It not only offers reliable measurements, but also user-friendly operation and versatile connection options.

Visualization of the transmission measurement in inhomogeneous products

What sets the HK1-MC apart

Digital microwave technology

Using the latest digital microwave technology in the ISM band, the HK1-MC guarantees precise measurements and reliable performance in cheese production.

Tailor-made for your success

The HK1-MC is designed to meet the unique requirements of cheese production. With optional cheese height measurement, we offer precise adaptation to your individual production conditions.

Robust reliability, constant precision

Vibrations that could affect measurement results in other environments are no obstacle for the HK1-Mc. This device remains maintenance-free and wear-free, ensuring consistent accuracy and reliability over time.

Remote control for maximum convenience

The HK1-MC is not only operated on site using six softkeys integrated into the membrane keypad, but can also be conveniently controlled from a PC or via a separate remote control. This means maximum flexibility and convenience for your production processes.

Technical data

Measuring method

Assembly technology

Stainless steel housing:

500 x 300 x 170 mm

Connections

Power supply:

100 – 240 V AC optional 24 V DC

Analog outputs:

2x 4 – 20 mA

Analog inputs:

1x 4 – 20 mA

PC interfaces:

RS 232 or RS 485

Relay contacts:

1x max. 5 A / 250 V

Digital inputs:

Ext. selection for 16 products, start, stop

PROFI-BUS-DP:

User interface

Operation:

6 softkeys integrated in the membrane keypad

Display:

2x 24 characters with backlight

Temperature ranges

Ambient temperature:

-20 °C to +85 °C

Product temperature:

≥0 °C to +130 °C

up to +140 °C on request

Antennas

Design: