Meat

Precise measurement technology in meat and sausage production

The demands placed on the meat industry are as varied as they are demanding. The innovative measuring systems from Harrer & Kassen provide meat processing companies with technologies that have been specially developed to meet their challenges. Whether measuring water content in raw meat, analyzing fat content in sausage products or processed products – our systems guarantee precise results and sustainably increase efficiency and product quality.

Precision and reliability in meat processing

Our measuring devices are tailored to the requirements of meat processing. They measure water content, fat, protein, salt and other specific ingredients with maximum accuracy.

NIR laboratory measuring devices expand the analysis options outside the production line and enable in-depth analysis of samples to provide optimum support for quality assurance and recipe development.

All technologies are characterized by high reliability and precision – even under demanding conditions in food production.

Your advantages

Versatile application options for our measuring devices

Raw meat

Fat, water and protein

Our measurement technology enables the precise determination of these parameters in raw meat. This is essential in order to achieve the desired consistency and ensure the quality of the subsequent production steps

Sausage production

Fat, water and proteins

Our measurement technology enables the precise determination of these parameters, as well as the calculation of various specific parameters, e.g. BEFFE. This ensures precise compliance with the respective recipes and therefore sausage products with optimum taste.

Additional benefits: NIR laboratory measuring devices make it possible to analyze product parameters and other quality parameters in raw materials and finished products when in-line measurement is not possible or practical.

Finishing products

Water and salt content analysis for premium products

For processed meat products such as ham or cured products, we offer specialized measuring technologies that precisely monitor the water and salt content. This supports consistently high quality and improves shelf life.

What sets our solutions for the meat industry apart

Optimization of product parameters

Harrer & Kassen enables precise measurement of the relevant parameters to optimize meat products. Our solutions ensure excellent products through precise control of production parameters.

Consistent product quality

Our measurement technology monitors and controls parameters such as water content, fat or protein to ensure consistent product quality and recipes. The solutions from Harrer & Kassen set standards for consistent quality.

Increased efficiency

Precise measurements contribute to the optimization of production processes, lead to the efficient use of resources and thus to cost savings. Our solutions aim to increase efficiency in meat processing.

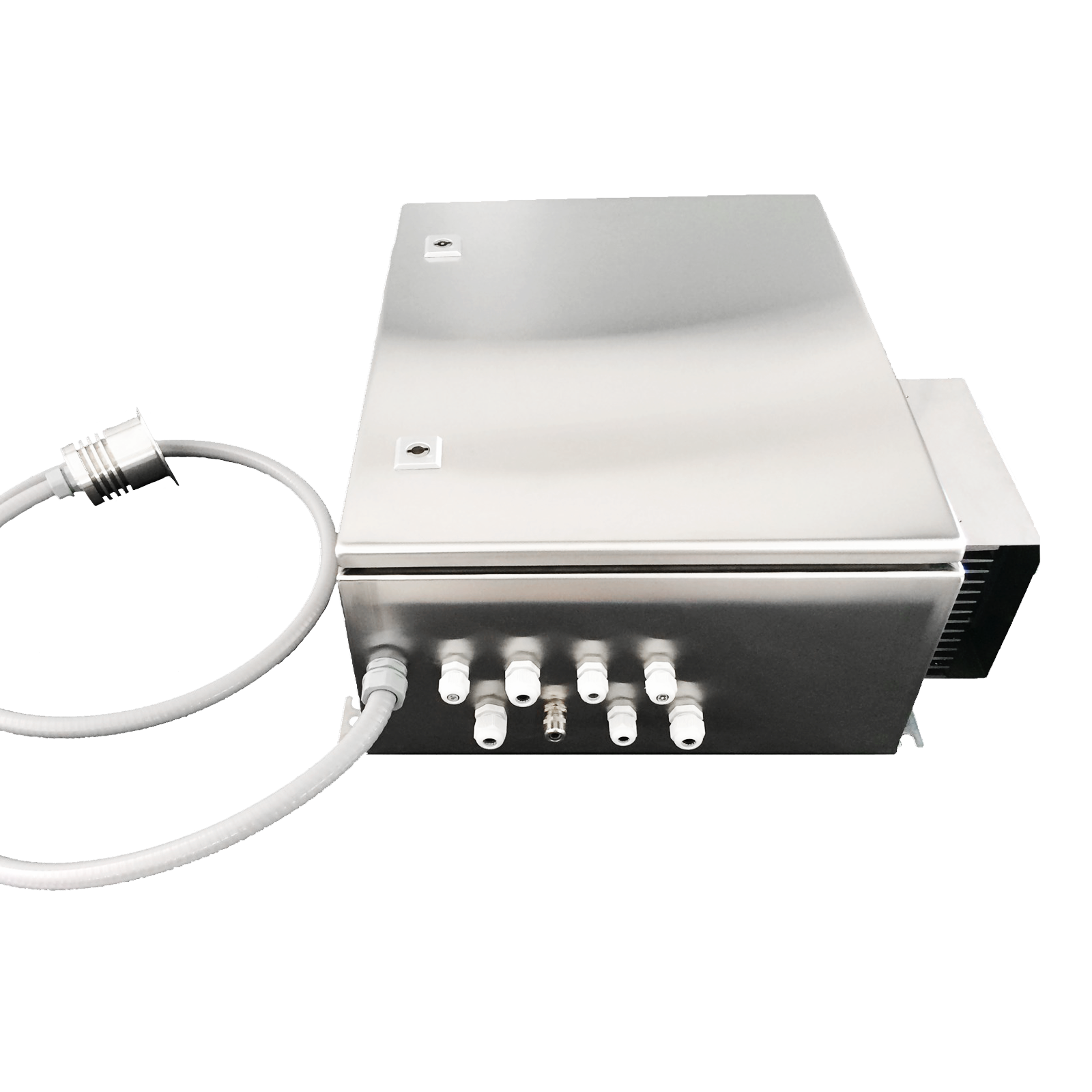

Our products for the meat industry

Industries: Gypsum, chemical industry, meat, dairy, mill products, cheese dairy, animal feed, other (blood)

Industries: Chemical industry, meat, dairy, cheese dairy, starch, mill products, animal feed