Animal feed

Precision and quality – Reliable measurement technology for animal feed production

The production of high-quality animal feed requires precise control of ingredients and production processes. Harrer & Kassen’s measuring systems enable reliable determination of moisture, composition and other critical parameters to ensure the quality of animal feed. Our technologies help to optimize production processes, save energy and ensure compliance with quality standards.

Our measuring devices are used in the following areas of the animal feed industry

Livestock

Feed quality for livestock plays a central role in modern agriculture. It significantly influences the health, growth, milk yield and meat quality of cattle, pigs, poultry and other livestock. Our high-precision measuring systems make it possible to precisely analyze and monitor the moisture content, dry matter, fat and protein content.

Thanks to continuous real-time measurement, producers can ensure that feed consistently meets the desired quality standards. Deviations in composition or moisture content can be detected and corrected at an early stage, leading to more efficient use of raw materials and greater profitability. In addition, the use of modern measurement technology reduces production losses and ensures that the animals are optimally supplied in order to fully exploit their performance potential.

Whether for large farms or specialized feed manufacturers – our measurement technologies offer solutions to optimize processes, conserve resources and meet the high demands of agriculture for feed quality.

Pets

The market for pet food is constantly growing, and with it the expectations of product quality. Pet owners attach great importance to a balanced, nutritious and safe diet for their pets, be it dry food, wet food or snacks. Precise measurement and control of ingredients is crucial to ensure quality, consistency and shelf life.

Our measurement technology enables the reliable determination of moisture content, fat content and other essential parameters throughout the entire production process. This ensures that pet food meets both the legal requirements and the high expectations of consumers.

Through continuous real-time monitoring, manufacturers can immediately detect deviations and adjust production processes to avoid wasting resources and increase efficiency. The results are clear benefits: consistent product quality, optimized production costs and satisfied customers.

With our measurement solutions, we help to ensure that pets receive high-quality, healthy and tasty food, while manufacturers benefit from the advantages of state-of-the-art process measurement technology.

Why process measurement technology is crucial in the animal feed industry:

Quality control

Our precise measuring devices ensure that feed has the optimum moisture content and nutrient composition. This ensures consistent feed quality and guarantees the animals’ nutrient supply.

Resource optimization

Accurate measurement of moisture and composition optimizes the use of raw materials, thereby cutting costs and reducing production waste.

Energy saving

Especially when drying animal feed, our moisture measurement technology enables efficient control of the drying processes in order to minimize energy consumption.

Process reliability

Our technologies offer continuous real-time monitoring of production processes to detect deviations immediately and avoid production errors.

Legal requirements

Process measurement technology helps to comply with strict legal regulations and quality standards, facilitates the documentation of production processes and contributes to the fulfillment of legal requirements.

Real-time monitoring

Advanced measurement technology enables real-time monitoring of processes in order to react quickly to deviations and minimize the risk of production errors.

Reproducibility

Precise measurements and reliable process control ensure consistent product quality – a decisive factor in the production of feed for livestock and pets.

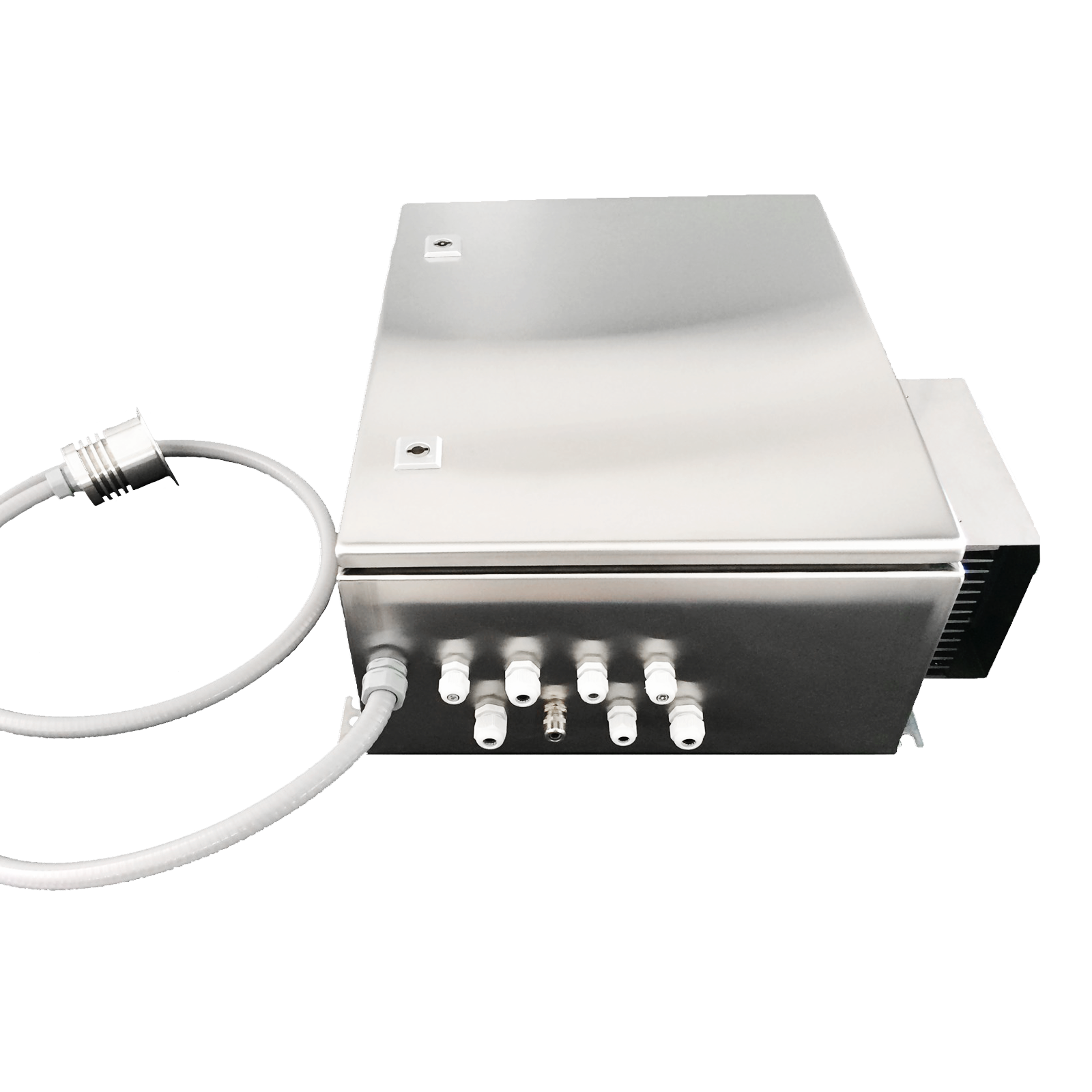

Our products for the animal feed industry

Industries: Waste water, chemical industry, dairy, starch, tobacco (tobacco cuttings), animal feed

Industries: Waste water, chemical industry, dairy, starch, tobacco (tobacco cuttings), animal feed

Industries: Gypsum, chemical industry, meat, dairy, mill products, cheese dairy, animal feed, other (blood)

Industries: Waste water, gypsum, floor coverings, sand, wood, clay, fiberboard, chemical industry, dairy, starch, sugar, paper, tobacco (tobacco cuttings), animal feed

Industries: Waste water, gypsum, floor coverings, sand, wood, clay, fiberboard, chemical industry, dairy, starch, sugar, paper, tobacco (tobacco cuttings), animal feed

Industries: Chemical industry, meat, dairy, cheese dairy, starch, mill products, animal feed