Sugar industry

Efficient solutions for precise sugar production

Precision and efficiency play a crucial role in the sugar industry. Our innovative measuring systems help to optimally monitor and control all production steps – from raw processing to crystallization and pellet production. Whether moisture measurement, Brix measurement or ICUMSA measurement – our technologies provide precise real-time data that enables producers to optimize processes, save energy and ensure the quality of the end product.

Advanced process monitoring for sugar production at the highest level

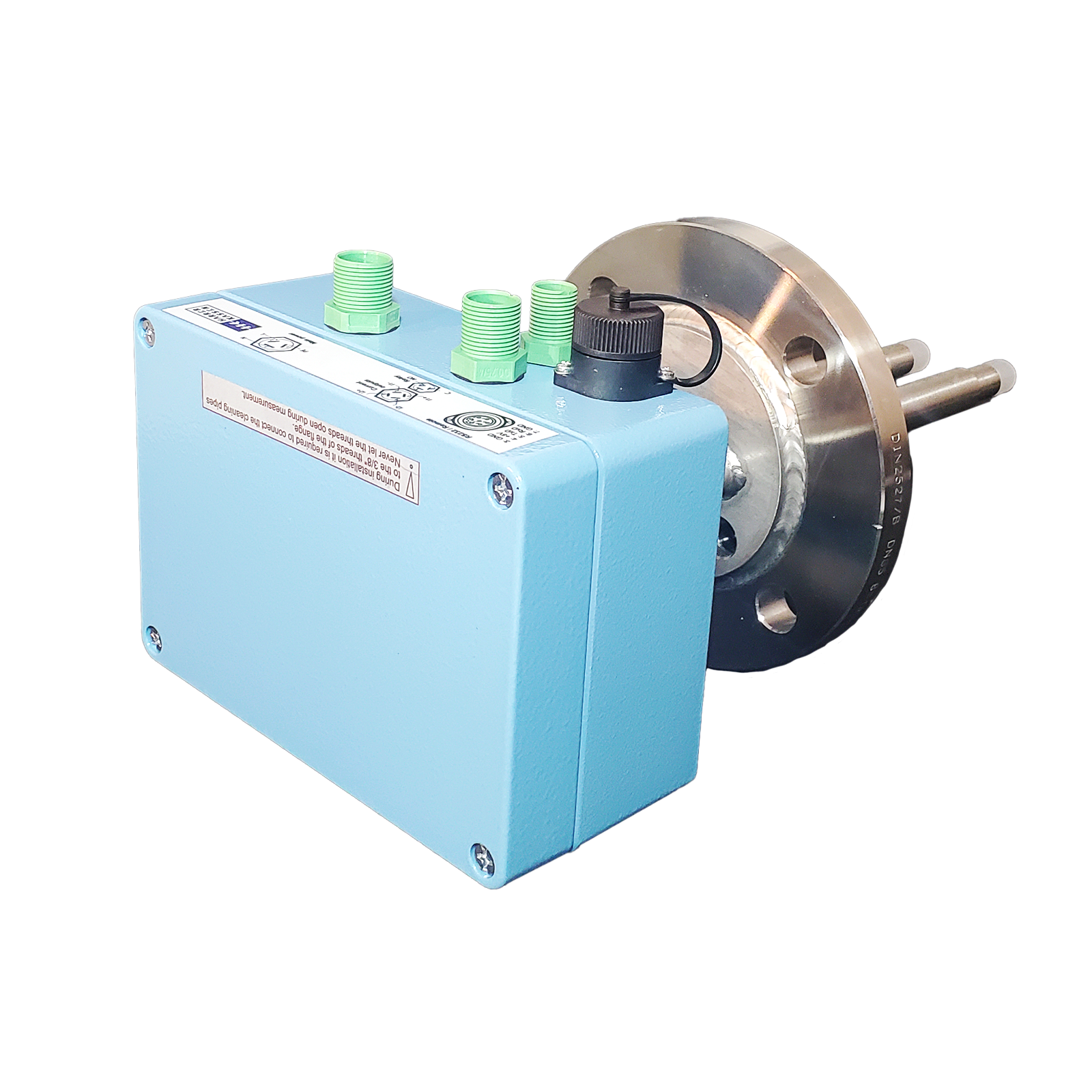

Our microwave measuring devices and our optical measuring devices are specially designed for the sugar industry. Microwave measurement technology enables precise Brix measurement in all production steps. NIR technology enables non-contact measurement of dry matter or water content, e.g. of beet pulp or bagasse, and VIS technology (visable) enables non-contact ICUMSA measurement.

All technologies deliver robust and reliable measurement results – even under demanding production conditions.

Your advantages

Versatile application options for our measuring devices

Thin juice

Thin juice is the starting point for sugar extraction. Our measuring devices enable exact BRIX measurement and precise monitoring of the concentration. Continuous control of the parameters ensures that the process runs efficiently and subsequent evaporation stages are optimally controlled.

Milk of lime

Milk of lime plays a central role in sugar purification by binding impurities from the sugar juice. Our measuring devices monitor the composition and concentration of milk of lime to ensure optimum purification performance and avoid wasting resources.

Thick juice

Thick juice, a concentrated sugar juice, requires precise BRIX measurement to ensure the quality of the end product. Our measurement technology provides real-time data for concentration measurement, which helps to control the evaporation process efficiently. This minimizes energy losses and ensures consistent product quality.

Crystallization

Crystallization is a critical step in sugar production that requires precise control. Our technologies enable the precise measurement of sugar concentration for accurate determination of the seeding point to ensure the formation of uniform and high quality crystals.

Color measurement

The color of sugar is an important quality criterion for the processing industries. Our spectrophotometers provide precise measurement results for monitoring color quality throughout the entire production process – from the centrifuge to the storage silo.

Beet pulp

Beet pulp, a by-product of sugar production, is often used as animal feed. Our moisture measurement systems help to control the water content in order to optimize drying processes and improve the storability of the pulp.

Bagasse (only for cane sugar)

Bagasse, the fibrous residue after sugar extraction, is often reused as a fuel or raw material. Our moisture measurement systems make it possible to precisely determine the residual water content in order to optimize drying processes and minimize energy consumption. As a result, bagasse is used more efficiently and combustion quality is improved.

What sets our solutions for the sugar industry apart

Precision in sugar production

The exact measurement of BRIX, dry matter and water content, as well as ICUMSA, ensures the quality of the end product and production processes are precisely controlled.

Optimal use of raw materials

Our measurement technology helps to efficiently process valuable raw materials such as beet pulp and bagasse, minimize losses and make optimum use of by-products.

Energy saving

Our measurement technology ensures efficient processes and significant savings in energy consumption, particularly in the drying of by-products and the evaporation of juices.

Consistent quality

From crystallization to colour measurement – our systems deliver reliable results to meet the highest quality requirements for sugar and by-products.

Process stability and safety

Continuous monitoring of critical parameters ensures safe, stable and reproducible production processes.

Real-time monitoring and optimization

Thanks to state-of-the-art measurement technology, sugar producers receive real-time data to immediately detect deviations and continuously optimize production processes.

Our products for the sugar industry

Industries: Waste water, gypsum, floor coverings, sand, wood, clay, fiberboard, chemical industry, dairy, starch, sugar, paper, tobacco (tobacco cuttings), animal feed

Industries: Waste water, gypsum, floor coverings, sand, wood, clay, fiberboard, chemical industry, dairy, starch, sugar, paper, tobacco (tobacco cuttings), animal feed