Chemical industry

Precise measurement technology for chemical processes

In the chemical industry, precision and efficiency are essential in order to manufacture high-quality products and meet stringent requirements. The measuring devices from Harrer & Kassen are specially designed to measure material parameters such as moisture, density and composition in real time. Our innovative solutions ensure optimized production processes, lower costs and consistent product quality – even with demanding applications and materials such as aluminium hydroxide, calcium carbonate and quartz sand.

Our measuring devices are used in the following areas of the chemical industry

Aluminum hydroxide, calcium carbonate

The precise monitoring of moisture in aluminum hydroxide is essential for the quality and efficiency of industrial processes. Our measuring devices enable fast and non-contact moisture measurement directly in the production line.

Thanks to their ability to reliably analyze even inhomogeneous products, our systems are ideal for drying monitoring and the optimization of grinding and screening processes. The robust design guarantees trouble-free measurements even under harsh operating conditions.

Quartz sand

The processing of quartz sand, particularly in the glass, foundry or building materials industries, requires precise monitoring of the moisture content. Our measuring devices deliver precise measurement results even with widely varying material conditions and inhomogeneous products.

With their maintenance-free design and the option of installation in transport lines, silos or conveyor belts, they offer a durable and efficient solution for optimizing production processes.

Moisture measurement in general

For moisture measurement in the chemical industry, our measuring devices offer an unbeatable combination of precision, stability and speed. The measuring devices record the moisture content in various materials such as powders, granulates or pastes and thus enable optimum process control.

From monitoring incoming materials to controlling drying processes – our systems ensure reliable quality control and maximum efficiency.

Why process measurement technology is crucial in the chemical industry:

Precision in demanding processes

The chemical industry requires measurement solutions that deliver reliable results even under extreme conditions. Our technologies are tailored to the specific requirements of complex chemical processes.

Process reliability

Our measurement technology enables the continuous monitoring of critical parameters in order to detect deviations at an early stage and design safe production processes.

Quality assurance

By precisely controlling the material properties, our devices ensure compliance with quality standards and improve the reproducibility of products.

Energy efficiency

For materials such as quartz sand or aluminum hydroxide in particular, our moisture measurement technology helps to efficiently control energy-intensive drying processes and reduce energy consumption.

Optimized use of raw materials

Thanks to precise measurements of moisture and composition, our systems help to use raw materials efficiently, avoid overdosing and reduce production waste.

Our products for the chemical industry

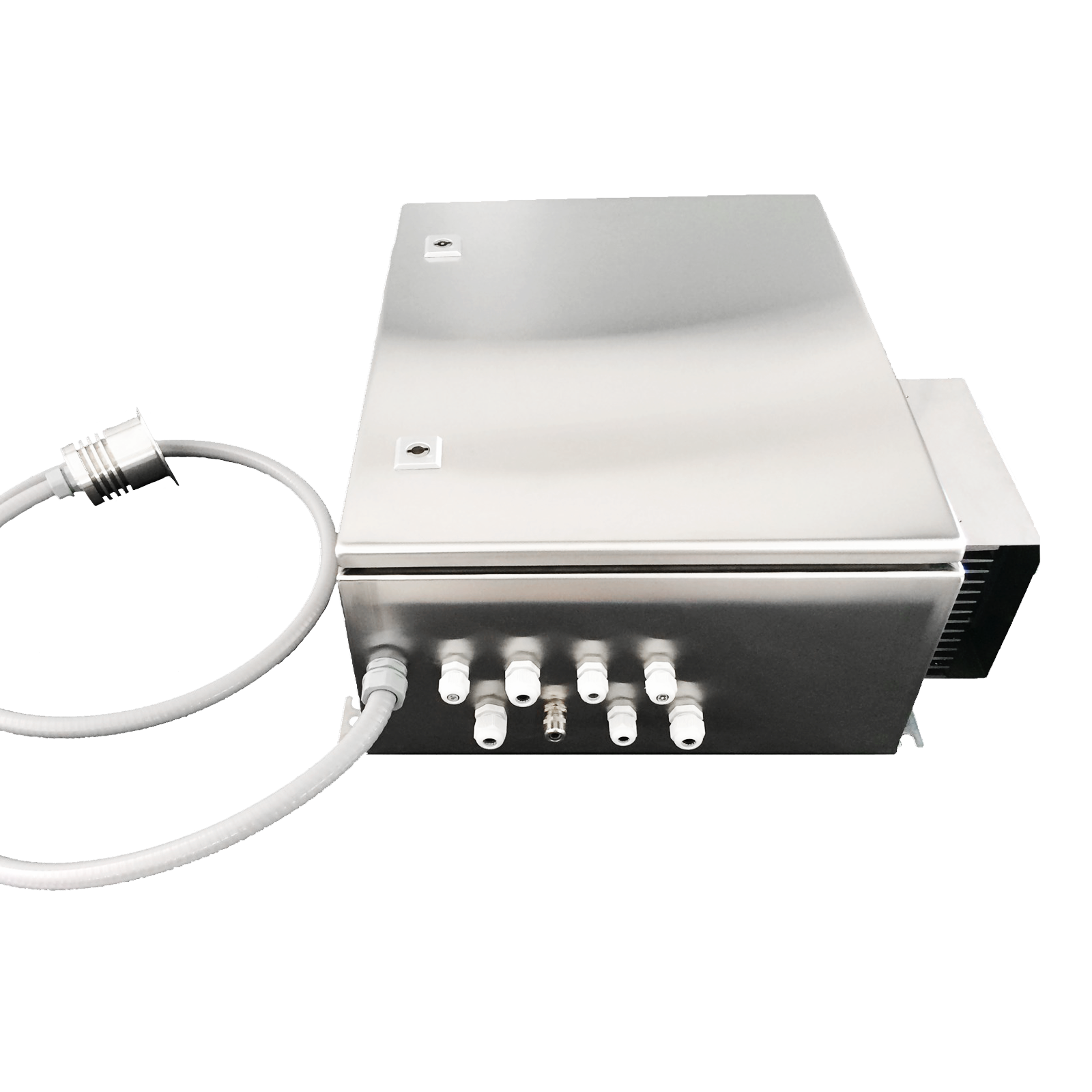

Industries: Waste water, chemical industry, dairy, starch, tobacco (tobacco cuttings), animal feed

Industries: Waste water, chemical industry, dairy, starch, tobacco (tobacco cuttings), animal feed

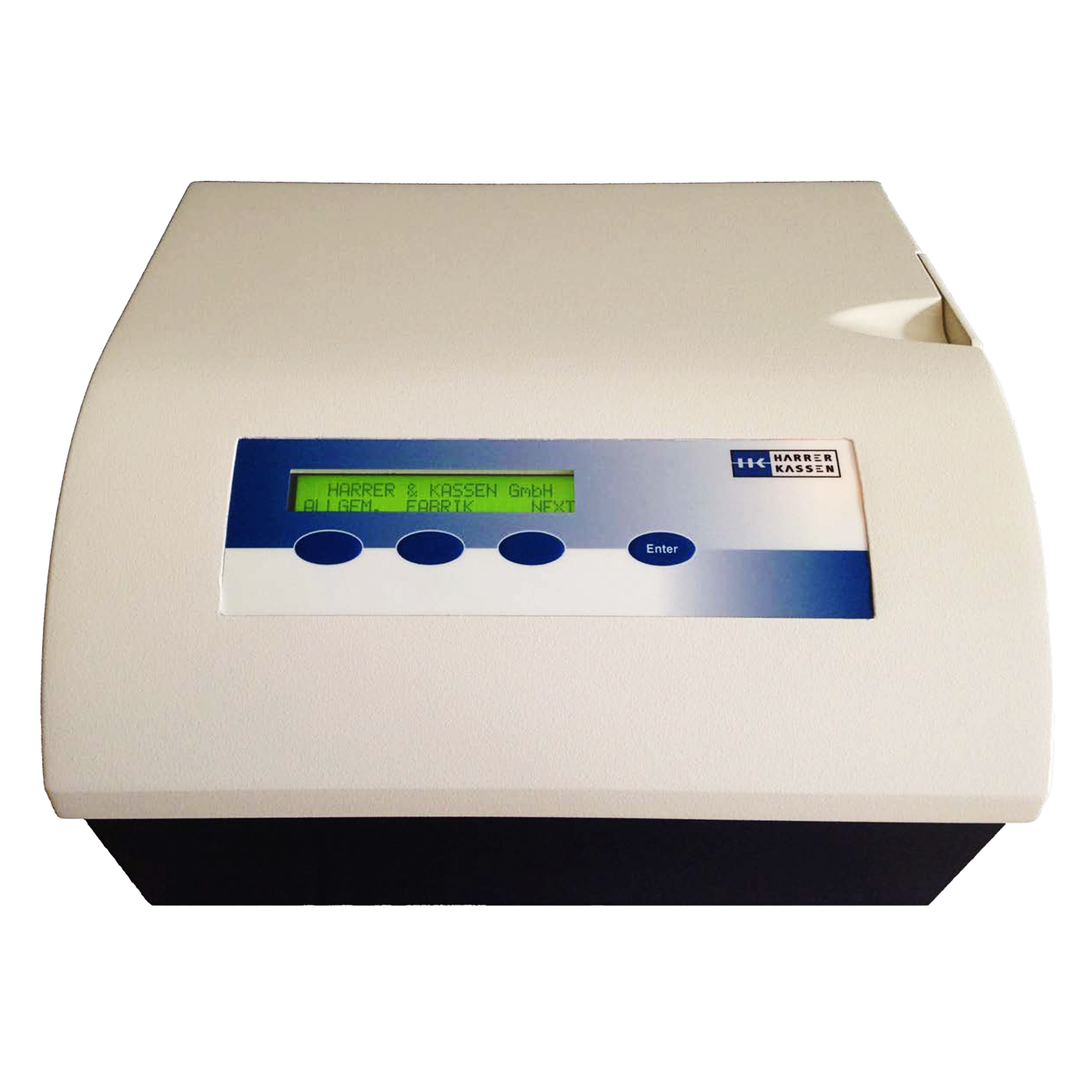

Industries: Gypsum, chemical industry, meat, dairy, mill products, cheese dairy, animal feed, other (blood)

Industries: Waste water, gypsum, floor coverings, sand, wood, clay, fiberboard, chemical industry, dairy, starch, sugar, paper, tobacco (tobacco cuttings), animal feed

Industries: Waste water, gypsum, floor coverings, sand, wood, clay, fiberboard, chemical industry, dairy, starch, sugar, paper, tobacco (tobacco cuttings), animal feed

Industries: Chemical industry, meat, dairy, cheese dairy, starch, mill products, animal feed